Technical Specifications

| Item | Content | ||

| Model | No. | Capacity | Operation |

| MJT-100 | 100KG/H | Fully continuous | |

| MJT-500 | 500KG/H | Fully continuous | |

| MJT-1000 | 1000KG/H | Fully continuous | |

| MJT-2000 | 2000KG/H | Fully continuous | |

| MJT-3000 | 3000KG/H | Fully continuous | |

| MJT-5000 | 5000KG/H | Fully continuous | |

| Accepted materials | Rice husk, saw dust, wood waste, straw, palm shell, coconut shell, | ||

| End products | Biochar/Charcoal, Syngas, Tar& Wood vinegar(optional) | ||

| Applicable fuel | Coal/natural gas/LPG/ Diesel/wood/pyrolysis oil | ||

| Material of reactor | 304 stainless steel | ||

| Reactor structure | Double cylinders | ||

| Cooling | Water Cooling | ||

| Land Required | 300-400m2 | ||

Raw Materials

Rice husk

Woody waste

Straw

Coconut shell

Jute rod

Sludge

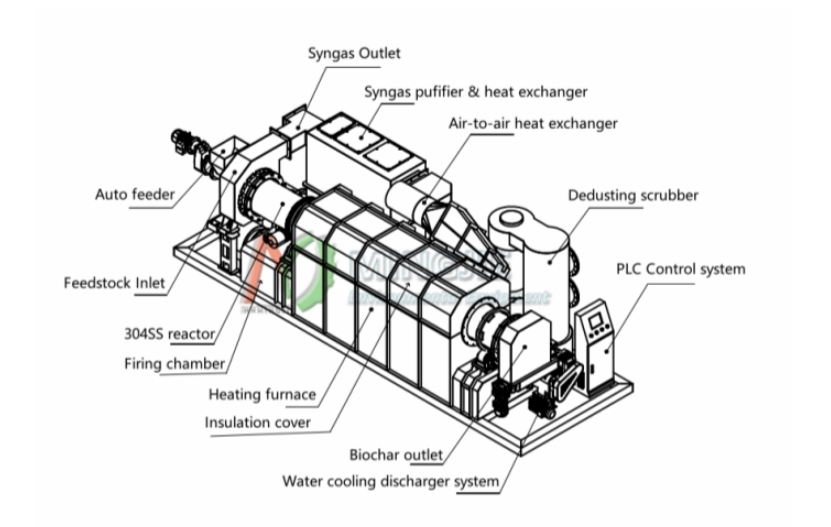

Advantages of the System

- Good as to be Pilot project for make demostration for invetors, government and verify the technology before setting big scale equipment.

- Skid mounted &Containerized design, compact structure, easy transportation and move.

- The key parts made of 304 stainless steel, can resist high temperature and corrosion, good applicability, long service life.

- 100% free installation, needs no civil work, can be put into use when unloaded from container.

- Fully Continuous running, PLC control, high level of automation, can be operated by 1 labor .

- Extreme energy saving design, two heat exchangers, greatly take use of the rest heat, save energy, high heat using efficiency.

— Air to air heat exchanger, warm-up combustion-supporting air, Increase waste heat utilization rate by 40%.

— Smoke and Syngas heat exchanger, Secondary heat the syngas to avoid tar & wood vinegar production, prevent the piping from jamming, greatly extend the continuously running time.

- Material release syngas during the carbonization process, after the purification, the syngas will be recycled as fuel for carbonization reactor heating and the first dryer heating.

- To pyrolysis, dehydrogenation, condensation and hydrogenation of aromatic compounds generated in the previous process.

Final Products

| Name | Picture | Application |

| Biochar/Charcoal |  |

Used as soil conditioner, carbon sequestration, improve the quality of soil Used as fuel for industry heating and cooling or BBQ Can be reprocessed into activated carbon, widely used in the smelting, chemical fields. |

| Syngas |  |

Can be recycled to heat the carbonization host. By this way, you can reduce a lot of fuel costs. |

Main Parts

Our Advantages

OEM

We are original manufacturer,has the ability to do customized design, keep competitive prices

Experience

We have more than 20 years manufacturing experience, 10 years exporting experience

R&D

We have R&D department, to do technology upgrading and new products research, clients have the chance to share the latest innovation

Service

Mingjie will provide seamless service

from our first communication, after-sale service has the beginning but never has the end

Investment

With constant financial support, Mingjie also looking for possibilities of investment overseas

Overseas Office

Mingjie has overseas office in the

Philippines and Brazil, has its own runing factory in Thailand, we can do the local technical and installation service. Solve the clients’ problems in the most efficient way.