· Product: MJ-15 pyrolysis plant

· Country: South Africa

On March 21, 2025, Mingjie Group successfully completed the delivery of 3 sets of plastic pyrolysis plants. They were transported to South Africa and used to process waste plastics and tires.

South African customers want to process 40 tons of waste plastics and tires every day. We recommended three MJ-15 pyrolysis plants and one MJZ-20 pyrolysis oil distillation plant.

We use 10 sets of 40HC containers and 4 sets of 40fr containers for packaging and transporting waste plastic pyrolysis plant and distillation plant.

Mingjie's engineering team is expected to arrive in South Africa at the end of April. They will install and fully test the equipment. At the same time, the Mingjie team will provide comprehensive operational training to workers to ensure that the pyrolysis system achieves optimal performance.

Plastic Pyrolysis Plants can convert waste plastics into fuel oil, gas and carbon black, which can help alleviate the problem of plastic pollution. As a major economic power in Africa, South Africa has a significant demand for plastic waste management. Pyrolysis plants can process local waste plastics and reduce environmental pressure.

The MJ15 pyrolysis plant can process 15 tons of waste tires or plastics per day. The MJ-15 plastic pyrolysis plant adopts batch operation mode, with low investment and high return.

The plastic pyrolysis plant works in an oxygen-free or low-oxygen environment, and the temperature is generally controlled at 350-800℃. As the temperature rises, a series of complex pyrolysis reactions occur in the plastic. The final products of plastic pyrolysis include syngas, pyrolysis oil, and solid residue carbon black. The condensation system separates the cracking gas from the cracking oil, and the purification device can further remove impurities in the cracking gas.

As an energy product, pyrolysis oil supplements the deficiency of traditional fossil energy. With the continuous growth of energy demand and the gradual reduction of fossil energy reserves, its market demand potential is huge. Especially in some areas with high requirements for energy supply stability and strong promotion of clean energy.

Small molecular hydrocarbon compounds such as ethylene and propylene in pyrolysis products are important chemical raw materials. With the development of the chemical industry, the demand for basic chemical raw materials continues to increase. Obtaining these raw materials through pyrolysis of waste plastics can reduce dependence on traditional chemical raw materials such as oil and natural gas, which has cost advantages and environmental advantages, and has broad market prospects.

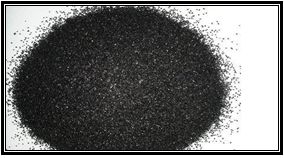

Processed carbon black is an indispensable reinforcing agent in the rubber industry, used to manufacture tires, rubber tubes and other products. In addition, it is also widely used in inks, coatings, plastics and other industries.

· Product: semi-continuous waste tires pyrolysis plant

· Country: Australia

· Nissan: daily capacity 30T

· Country: Lebanon